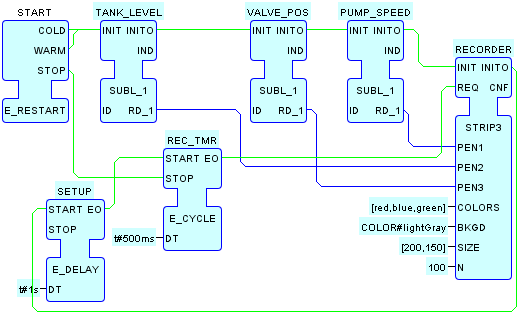

This System Configuration implements the Model+View testing step for the process control example.

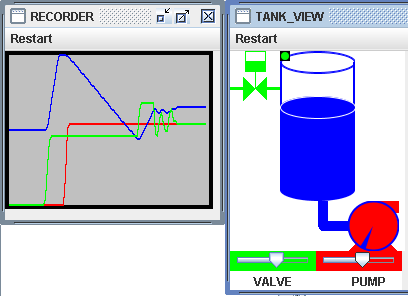

You can launch

this configuration from the FBDK

and use the sliders to adjust the

VALVE

and

PUMP

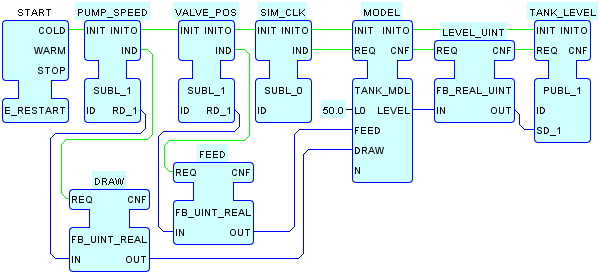

settings in the range {0..100}%. The

TANK

will rise and fall at a rate proportional to the difference between

the

VALVE

and

PUMP

settings.

This System configuration uses the Local Multicast design pattern for the communication of data and events among Resources. The FBDK uses the Tagged Data design pattern to ensure consistency of the communicated events and data, as shown in the table below.

| Name | Type | UDP Channel | Description |

|---|---|---|---|

PUMP_POS

|

INT

|

|

{-359..+359} degrees

|

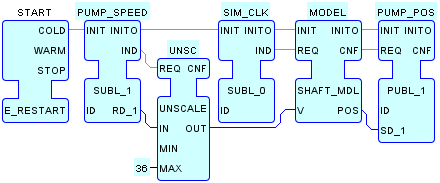

PUMP_SPEED

|

UINT

|

|

{0..100}% => {0..36} degrees per clock tick

|

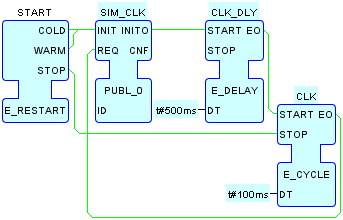

SIM_CLK

|

|

|

Simulation Clock

|

TANK_LEVEL

|

UINT

|

|

{0..100}%

|

VALVE_POS

|

UINT

|

|

{0..100}% => {closed..open}

|

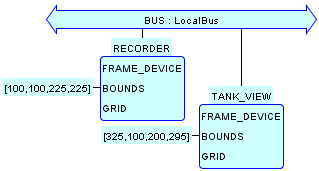

RECORDER device provides HMI functionality

via an instance of the STRIP3

class to record the system's dynamic behaviors.

TANK_VIEW device provides combined Model,

View and HMI functionality.

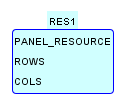

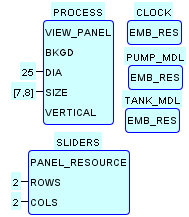

The TANK_VIEW.PROCESS

resource is configured identically to the TANK_VIEWL

system configuration to provide View functionality.

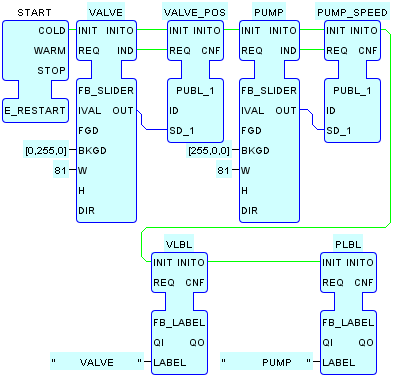

The TANK_VIEW.SLIDERS resource provides the HMI

functions for the setting of valve position and pump speed.

The TANK_VIEW.CLOCK, TANK_VIEW.PUMP_MDL and TANK_VIEW.TANK_MDL

Resources provide the simulation clock and Models for the

dynamic behavior of the Pump and Tank, respectively.