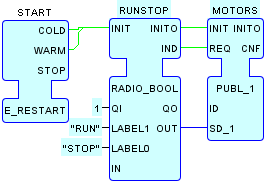

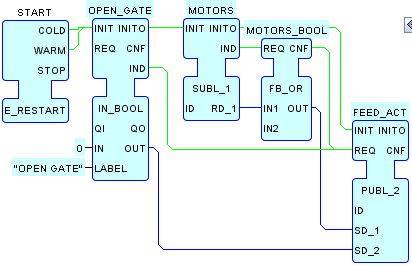

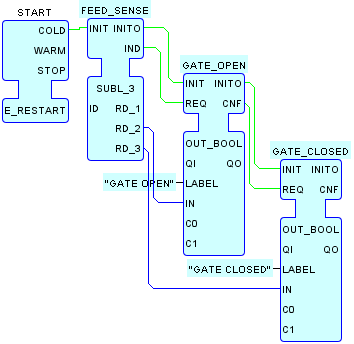

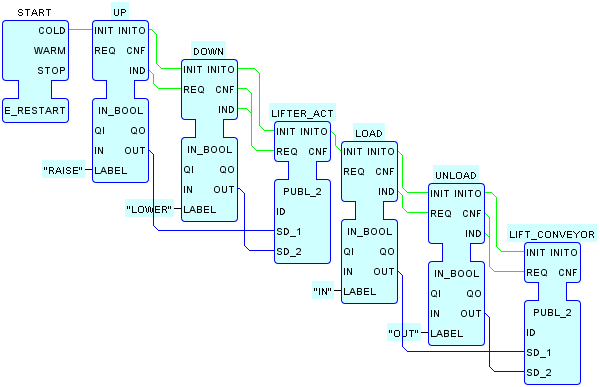

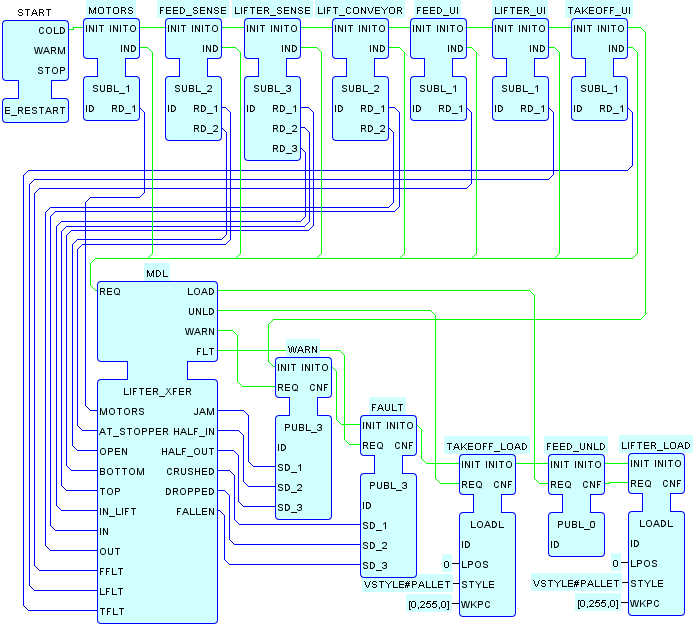

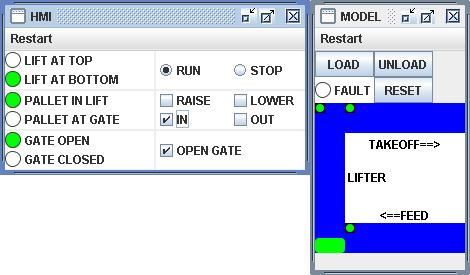

This System Configuration implements the layered Model+View testing architecture for the pallet handling example. The screenshot above shows the result of performing the following actions:

- Launching the configuration.

- Clicking the RESET button to initialize the system.

- Clicking the LOAD button to load a pallet onto the FEED conveyor.

- Clicking the RUN button to feed the pallet up to the closed gate.

- Clicking the IN button to start the lifter's internal conveyor running in the infeed direction.

- Clicking the OPEN GATE button to enable the pallet to be conveyed into the lifter.

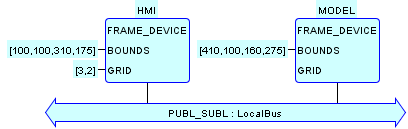

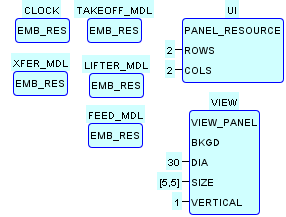

The HMI device encapsulates the functionality of the HMI

layer of the architecture - specifically the HMI elements needed to

read sensor values and write actuator values - while the MODEL

device encapsulates both the Model and the View

layers.

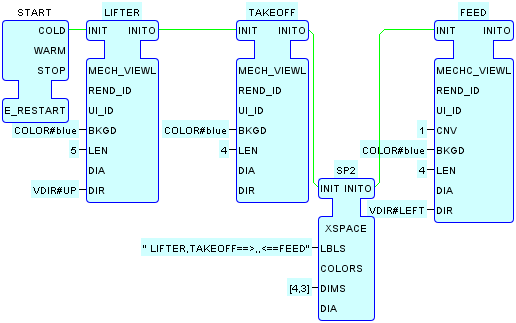

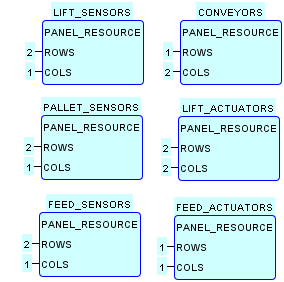

As in the VIEW device of the LIFTER_VIEWL

configuration, the MODEL device contains an instance of

the specialized VIEW_PANEL

resource type to provide the necessary layout of View

elements for the pallet handling example. In addition, an instance

of the PANEL_RESOURCE

type contains the User Interface (UI) elements necessary for

operation of the model, specifically:

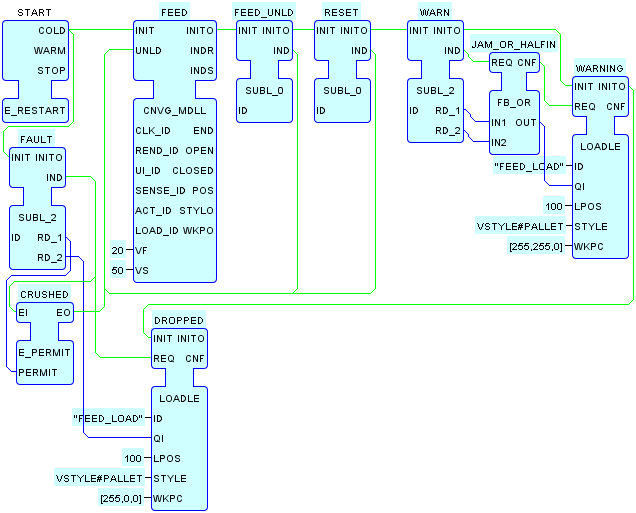

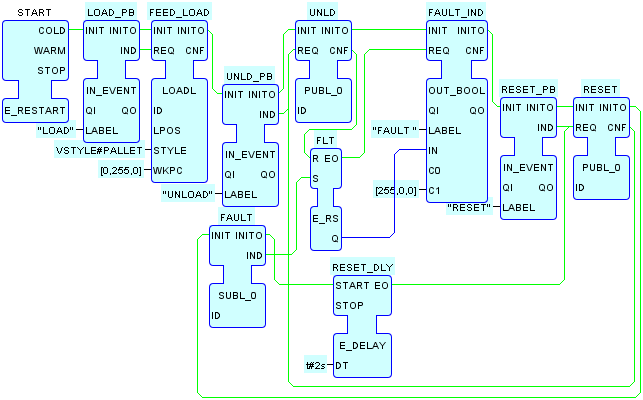

- Two pushbuttons to LOAD a pallet onto the feed conveyor and UNLOAD it from the takeoff conveyor, respectively.

- A FAULT output to indicate the existence of a fatal condition (which stops the simulation clock), and a RESET button to recover from the fault condition.

The MODEL device also

contains five instances of the EMB_RES

type, which in turn contain the Model elements for the

corresponding Views, as well as logic to simulate the physics

of the interactions among Model elements including their

sensors and actuators; transfer of workpieces; and simulation of

fatal and non-fatal fault conditions:

-

The

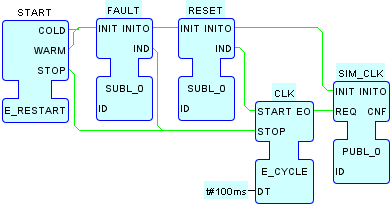

CLOCKresource contains the simulation clock, whose events are distributed using the local multicast pattern. -

The

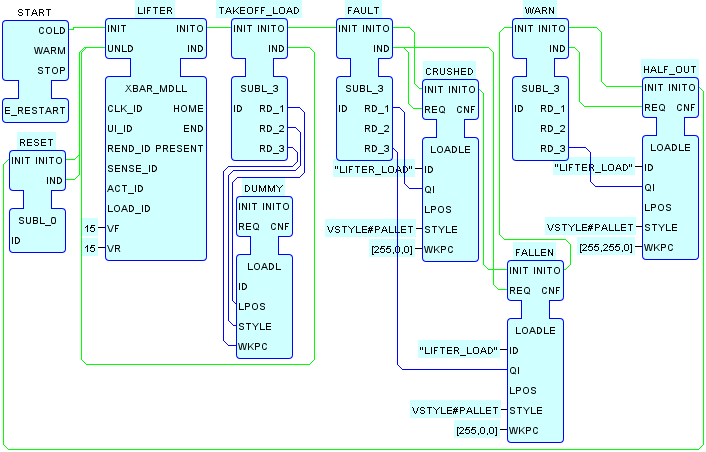

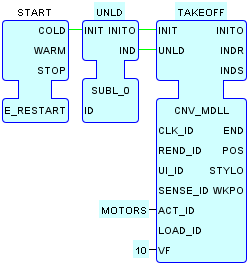

FEED_MDLresource contains an instance of theCNVG_MDLLtype, corresponding to the feed conveyor in theVIEWpanel, along with local multicast elements, logic and instances of theLOADLEtype to handle pallet transfer to the lifter element as well as display of fault conditions. -

The

LIFTER_MDLresource contains an instance of theXBAR_MDLLtype, corresponding to the lifter element in theVIEWpanel, as well as elements to handle pallet transfer and display of fault conditions in a manner similar to theFEED_MDLresource. -

The

TAKEOFF_MDLresource contains an instance of theCNV_MDLLtype, corresponding to the takeoff conveyor in theVIEWpanel, as well as elements to handle pallet transfer and display of fault conditions in a manner similar to theFEED_MDLandTAKEOFF_MDLresources. -

The

XFER_MDLresource contains an instance of theLIFTER_XFERtype to model the normal loading and unloading of pallets from the lifter as well as fatal and non-fatal fault conditions.

As shown in the table below, inter- and intra-layer communication is

implemented with the local multicast pattern, in particular for the

distribution of the simulation clock and the simulation of workpiece

transfer with instances of the LOADLE

type. The Tagged Data

design pattern to ensure consistency of the communicated events and

data.

| Tag Name | Type(s) | Description |

|---|---|---|

FAULT

|

BOOL,BOOL,BOOL

|

CRUSHED, DROPPED, FALLEN

|

FEED_ACT

|

BOOL,BOOL

|

FEED_MOTOR, GATE_DOWN

|

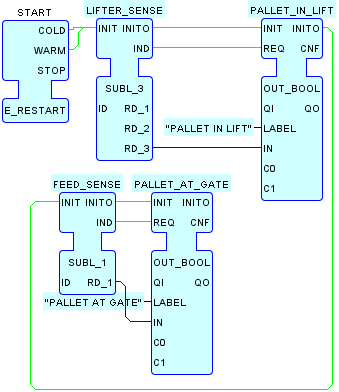

FEED_SENSE

|

BOOL,BOOL,BOOL

|

PALLET_AT_GATE, GATE_OPEN, GATE_CLOSED

|

FEED_UI

|

BOOL

|

User input FAULT Condition from MODEL.VIEW.FEED

|

FEED_UNLD

|

|

Unload Pallet from FEED conveyor

|

LIFTER_ACT

|

BOOL,BOOL

|

RAISE, LOWER

|

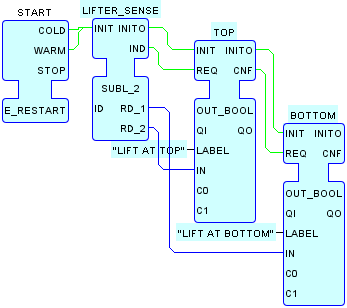

LIFTER_SENSE

|

BOOL,BOOL,BOOL

|

BOTTOM, TOP, PALLET_IN_LIFT

|

LIFTER_UI

|

BOOL

|

User input FAULT Condition from MODEL.VIEW.LIFTER

|

LIFT_CONVEYOR

|

BOOL,BOOL

|

IN, OUT

|

MOTORS

|

BOOL

|

FEED + TAKEOFF MOTORS

|

RESET

|

|

RESET Command from MODEL.UI

|

SIM_CLK

|

|

Simulation Clock

|

TAKEOFF_LOAD

|

UINT,VSTYLE,COLOR

|

LPOS, STYLE, WKPC from MODEL.XFER_MDL

|

TAKEOFF_UI

|

BOOL

|

User input FAULT Condition from MODEL.VIEW.TAKEOFF

|

UNLD

|

|

UNLOAD Command from MODEL.UI

|

WARN

|

BOOL,BOOL,BOOL

|

JAM, HALF_IN, HALF_OUT

|