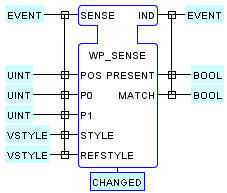

EVENT_INPUT

SENSE WITH STYLE,REFSTYLE,POS,P0,P1;

(* Input change notification *)

END_EVENT

EVENT_OUTPUT

IND WITH PRESENT,MATCH;

(* Output change indication *)

END_EVENT

VAR_INPUT

POS : UINT;

(* Workpiece position on conveyor (0-100%) *)

P0 : UINT;

(* Position sensor lower limit *)

P1 : UINT;

(* Position sensor upper limit *)

STYLE : VSTYLE;

(* Workpiece style *)

REFSTYLE : VSTYLE;

(* Style to be sensed *)

END_VAR

VAR_OUTPUT

PRESENT : BOOL;

(* Workpiece is present between P0 and P1 *)

MATCH : BOOL;

(* Workpiece is present and STYLE matches REFSTYLE *)

END_VAR

VAR

CHANGED : BOOL;

(* PRESENT and/or MATCH value has changed *)

END_VAR

An instance of this function block type models the operation of a

dual set of sensors which can sense both the presence of a workpiece

at a position POS between the two positions

P0

and

P1

inclusive, and whether the type of the workpiece given by the

STYLE

input matches the reference style

REFSTYLE

(an instance of the VSTYLE data

type) when the workpiece is present. It is typically used to position

a sensor pair at a specified location along a conveyor modelled by an

instance of the CNV_MDL type

or its enclosing CNV_MDLL or

CNVG_MDLL types, for

instance as in the sortation/inspection

testbed.

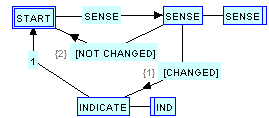

As modeled by the Execution Control Chart (ECC) and Algorithm shown

below, the operation of the block is triggered by an event at the

SENSE

input and results in an event at the

IND

output when the value of either or both of the

PRESENT

and

MATCH

sensors changes.

ALGORITHM SENSE IN Java :

final boolean newpres

= (POS.value>=P0.value)

&& (POS.value<=P1.value)

&& (STYLE.value != VSTYLE.NONE);

final boolean newmatch

= newpres && (STYLE.equals(REFSTYLE));

CHANGED.value

= (newpres != PRESENT.value)

||(newmatch != MATCH.value);

if(CHANGED.value){

PRESENT.value = newpres;

MATCH.value = newmatch;}

END_ALGORITHM